OXO-BIODEGRADABLE ADDITIVE MASTERBATCH

Download Oxo-Biodegradable brochure

In response to the UAE’s commitment towards promoting an eco-friendly global environment, we have created Oxo-Biodegradable (OBD) additives that offer an environmental friendly alternative to both plastic manufacturers and consumers. This sustainable solution modifies commodity plastics and ensures increased environmental responsibility. EnerPlastics OBD additives convert long-life polyolefin plastic bags to harmlessly degrade after a pre-programed lifespan of complete mechanical integrity, and is therefore an optimum approach to combat environmental pollution and its consequences.

The mechanism of polyethylene biodegradation known as Oxo-Biodegradation occurs in two stages, these are:

- Abiotic (photo or thermo) oxidation

- Microbial biodegradation

Initial abiotic oxidation is an important stage as it determines the rate of entire process. In this stage polyethylene is oxidized leading to reduction of its molecular weight significantly. Also hydroxyl (-OH), carbonyl (C=O) and carboxylic (-COOH) groups are introduced into polyethylene chain leading to further oxidation of polyethylene.

The main factors that influence abiotic oxidation are heat and sunlight. They are crucial for both reduction of molecular weight and the production of low molecular weight compounds that can be assimilated easily by the microorganisms.

ENERPLASTICS OXO-BIODEGRADABLE ADDITIVE MASTERBATCH

EnerPlastics OBD additive masterbatch are introduced to plastics films at manufacturing stage; the additives are dosed at very low level which ensures that the commercial product (film) would have a guaranteed mechanical strength and other properties for a minimum period (usually 12months) after manufacturing.

The organometallic constituents’ acts as a catalyst in oxidizing the polymer molecule to a state where it is converted as food to soil microbes, fungi, bacteria etc.

The metal part of the organometallic component are non-toxic to soil or food contact.

THE APPROACH ON TESTING MATERIAL ON DEGRADABILITY

Standard and Tests

Testing is a critical aspect of supporting an oxo-biodegradable product. EnerPlastics has a state of the art testing laboratory which is capable of performing oxo-biodegradable testing and determines the suitability of a formulation for given applications. Availability of number of weathering chambers, FTIR, XRF and tensile machines add to its capability in giving accurate test results.

The approach on testing material on degradability

AFNOR STANDARD ACT 51-808

Plastics: Assessment of oxobiodegradablity of polyolefinic materials in form of films- methodology and requirements.

In order to predict long term fate of polymeric material dispersed in environment, it is necessary to establish accelerated laboratory conditions. Studies of polyolefinic time course mechanisms have demonstrated that phenomena governing evolution in a natural environment are photothermal oxidations (under combined effect of light and heat) and thermooxidations. The progress of these oxidations is determined through accumulation of carboxylic acid groups that can be detected using FTIR spectrophotometer. The increase in absorbance at 1714cm-1 which determines the relative acid group contents can be expressed based on thickness of films.

ABIOTIC DEGRADATION ASSESSMENT METHOD

- Thermoxoidation (to guarantee minimum one year life time in storage and use in indoor conditions)

- Photooxidation (to guarantee the fragmentation of films that are scattered in the environment after approximately 3-5 months of exposure to sunlight)

- Thermooxidation of previously photo-oxidized films (that guarantees that films abiotically degraded after 3 months exposure to sunlight and acquired biodegradability in soil within 2-3 years)

ASTM STANDARD 6954-2018

ASTM 6954 Standard Guide for Exposing and Testing Plastics that Degrade in the Environment by a Combination of Oxidation and Biodegradation.

This describes the methodology of testing. In this standard oxobiodegradablity is described in three tiers:

Tier 1: Abiotic degradation to simulate environmental exposure to light and heat. The molecular weight is determined and it should be less than 5000dalton and there should be less than 5% gel.

Tier 2: Biometric measurement of fragments

Tier 3: Eco-toxicity testing

ESMA (UAE5009:2009) STANDARD

Standard and specification of oxo-biodegradation of plastic bags and other disposable plastic objects

Abiotic degradation test shall be performed and degradation shall be evaluated by measuring by loss in mechanical properties, decrease in molecular weight and determination of gel content.

After abiotic degradation average molecular weight should be less than 5000 dalton, gel fraction less than 5% and elongation at break less than or equal to 5% of original value.

BS STANDARD 8472:2011

Methods for the assessment of the oxo-biodegradation of plastics and of the phyto-toxicity of the residues in controlled laboratory conditions

The standard describes methods for determining

a) Degradation by oxidation (abiotic tests)

b) Biodegradation (biotic test in soil) and

c) Phyto-toxicity (plant growth tests) of plastics materials and products

SPECIALIZED PACKAGING ADVANTAGE

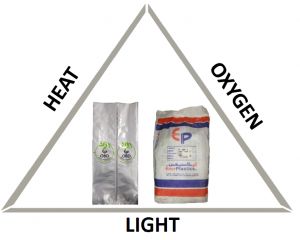

EP OBDs are commercially available in specialized multi layer and multi barrier 20kg packaging that provides protection against light and oxygen during the transport and storage of the additive.

EnerPlastics is the only Manufacturing Company in the MENA Region that provides two different grades of OBDs to meet varying customers and market requirements. Both grades are packed in vacuum sealed aluminum bags placed in Laminated PP Bags with PE Liners.

![]() EP OBD is susceptible to light, heat and oxygen. It is highly recommended that once the Aluminum bag is opened, it be consumed in the shortest time possible in order to perform its full function when mixed and blown into a film. To assist smaller film convertors, EnerPlastics can supply the product in identical packing of 10 Kg, subject to prior enquiry.

EP OBD is susceptible to light, heat and oxygen. It is highly recommended that once the Aluminum bag is opened, it be consumed in the shortest time possible in order to perform its full function when mixed and blown into a film. To assist smaller film convertors, EnerPlastics can supply the product in identical packing of 10 Kg, subject to prior enquiry.

SALIENT FEATURES AND BENEFITS OF EP OBD ADDITIVES

Shelf life: The shelf life and service life of degradable plastic using EP OBD can be customized based on customer requirements ranging from a few months to years depending on the type and amount of OBD that has been added to the plastic resin.

Processiblity: Processed in existing facilities with existing equipment and near identical processing parameters to conventional plastics.

Credentials: EnerPlastics OBD additives meet the requirements of all OBD standards existing in the market and have certificate from accredited organizations.

Free from Heavy Metals: All EnerPlastics OBD additives are free from heavy metals like cadmium, chromium, mercury, lead, arsenic.

Food Approved: Degradable additives made by EnerPlastics are non-toxic and safe for food contact applications.

Degradable and Biodegradable: Scientific studies show that EnerPlastics OBD additives are degradable and biodegradable.

EnerPlastics

|

|

|

Certified by ESMA according to UAE.S 5009:2009/ASTMD6954:2009 standard |

|

Certified by Saudi Standard, Metrology and Quality Org as per SASO 2879/2016 Degradable Plastic Products. |

|

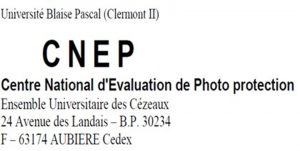

Certified by Centre National d’Evaluation de Photo Protection (CNEP), Université Blaise Pascal, France and Synthèse et Etude de Systèmes à Intérêt Biologique (SEESIB) as per AFNOR AC T51-808-2012. CNEP/SEESIB are the only research centers in the world that have been doing research on the degradation of plastics for 31 years. (Applicable for OBD-2) |

|

Tested in China National Centre for Quality Supervision & Test of Plastic Products according to GB/T 20197-2006 and HJ/T 209-2005 Standard of degradable plastics. (Applicable for OBD-2) |

|

AP (89) 1 food contact approval certificates from SGS |

|

EP OBD additive evaluation and studies done and validated at EP Advance Lab, an ISO/IEC 17025:2005 accredited Laboratory |

Certifications

Certifications